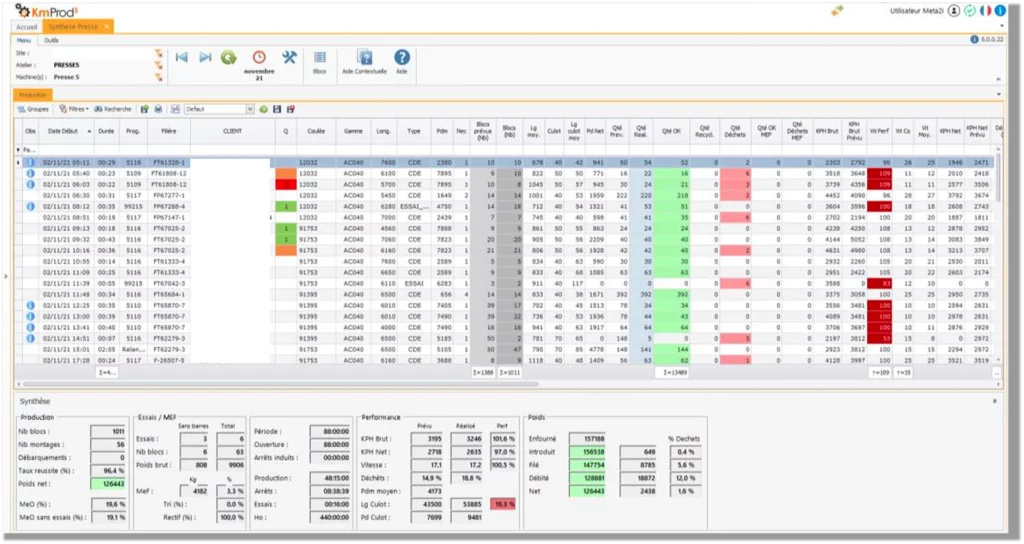

KmExtrusion is the essential tool for your production aluminium workshop

Created and edited by META 2i, with 30 years of MES (Manufacturing Execution System) experience, and crafted in collaboration with industry experts in aluminum extrusion, KmExtrusion is now the leading MES software on the aluminum extrusion market!

OUR HISTORY

META 2i and KmExtrusion

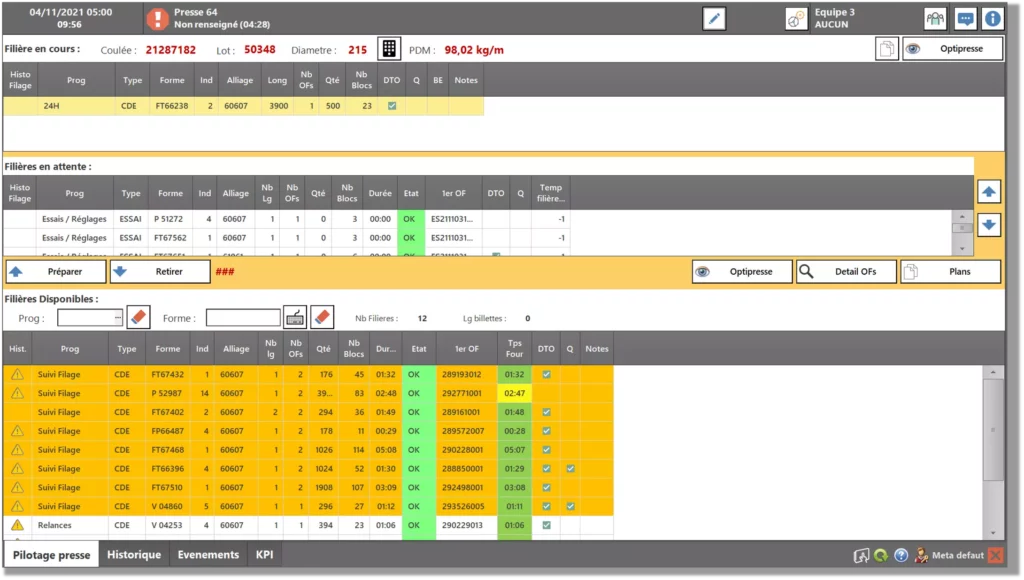

KmExtrusion is an adaptive and scalable MES solution specialized in the aluminum industry. It connects your entire company, from ERP (Enterprise Resource Planning) to machines.

KmExtrusion’s applications allow the development of specialized” profession” modules for each workshop. In addition, communication is easy, from the operator to the decision-maker. The result is an optimized and improved industrial information system for the entire production flow.

Thus, thanks to a collaboration between our teams and the field actors of the aluminium industry, we could realize modules adapted to each stage of the production. Today, META 2i continues to work with new customers in the world of aluminium as well as its historical customers to offer the most complete MES solution for the aluminium market.

KmExtrusion

Features and issues

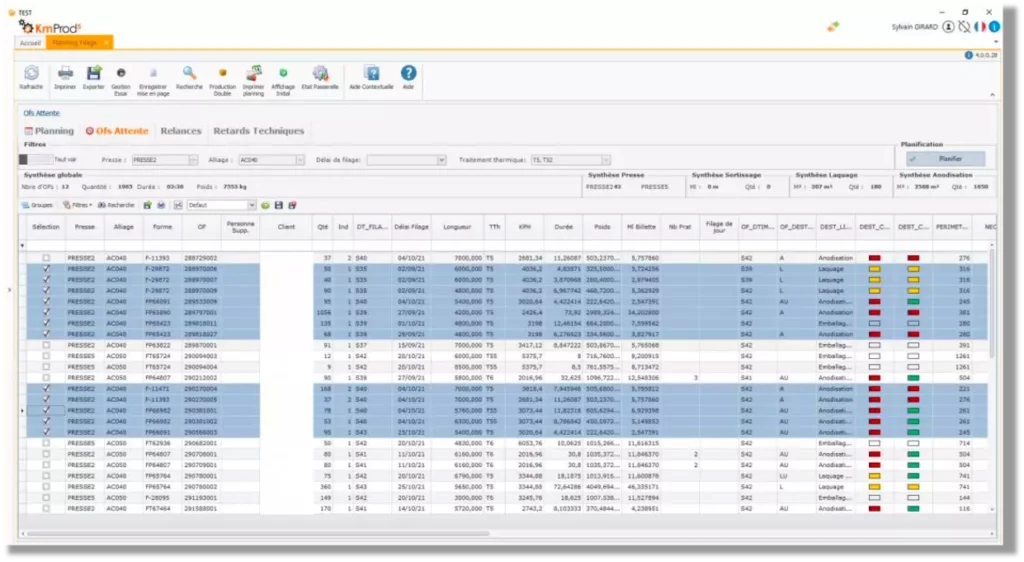

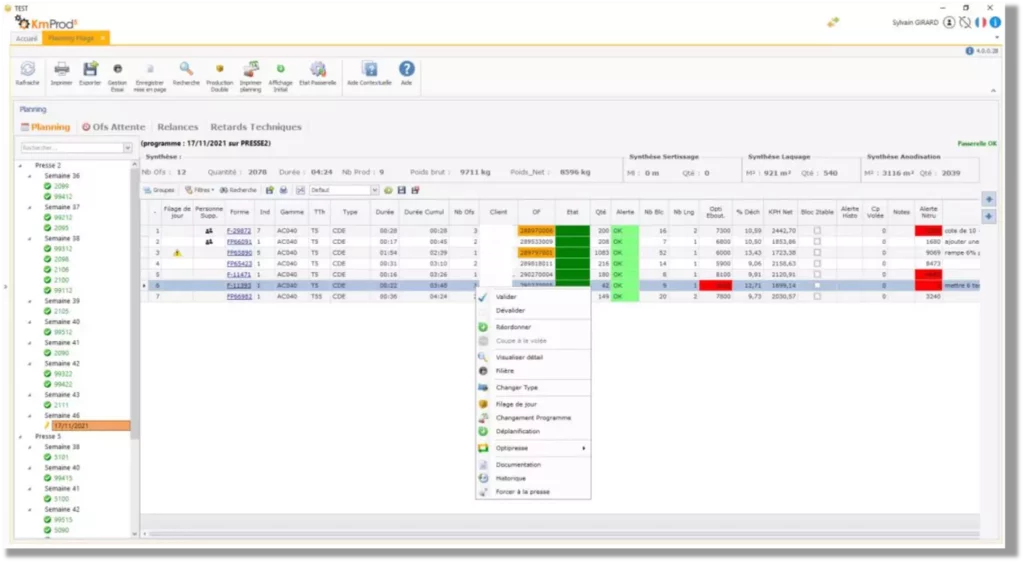

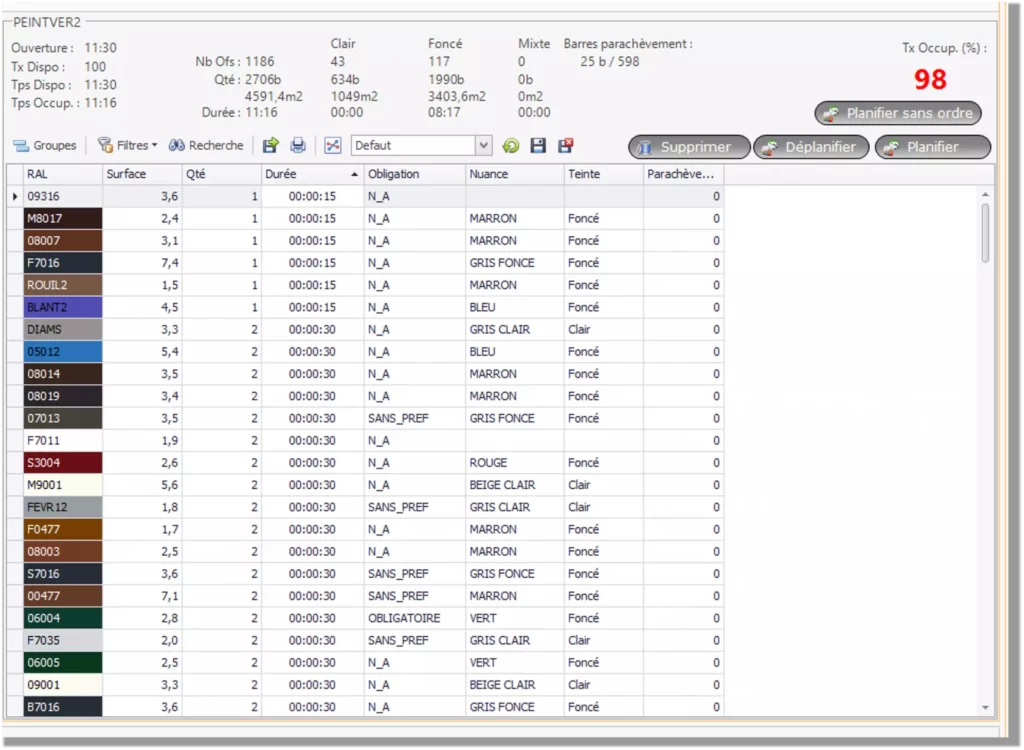

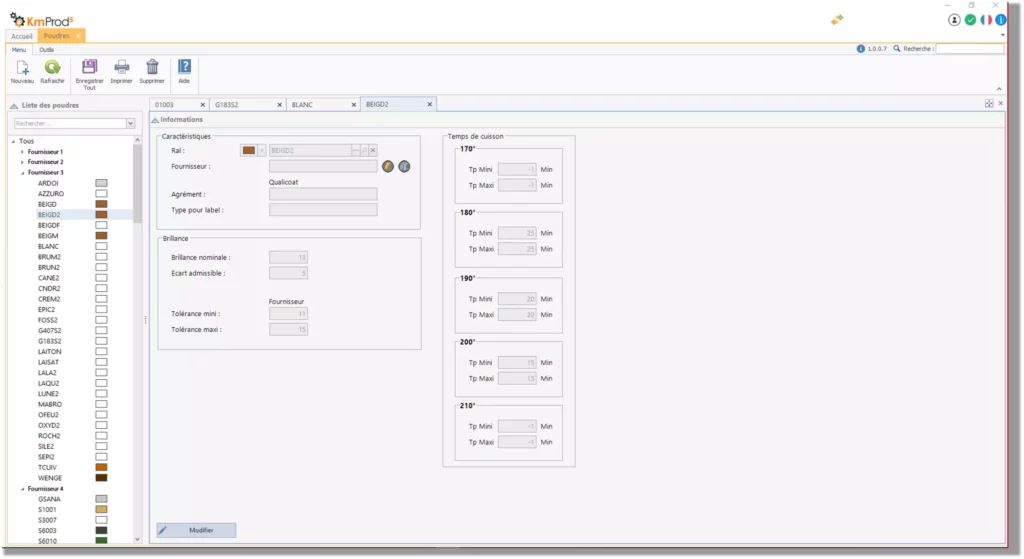

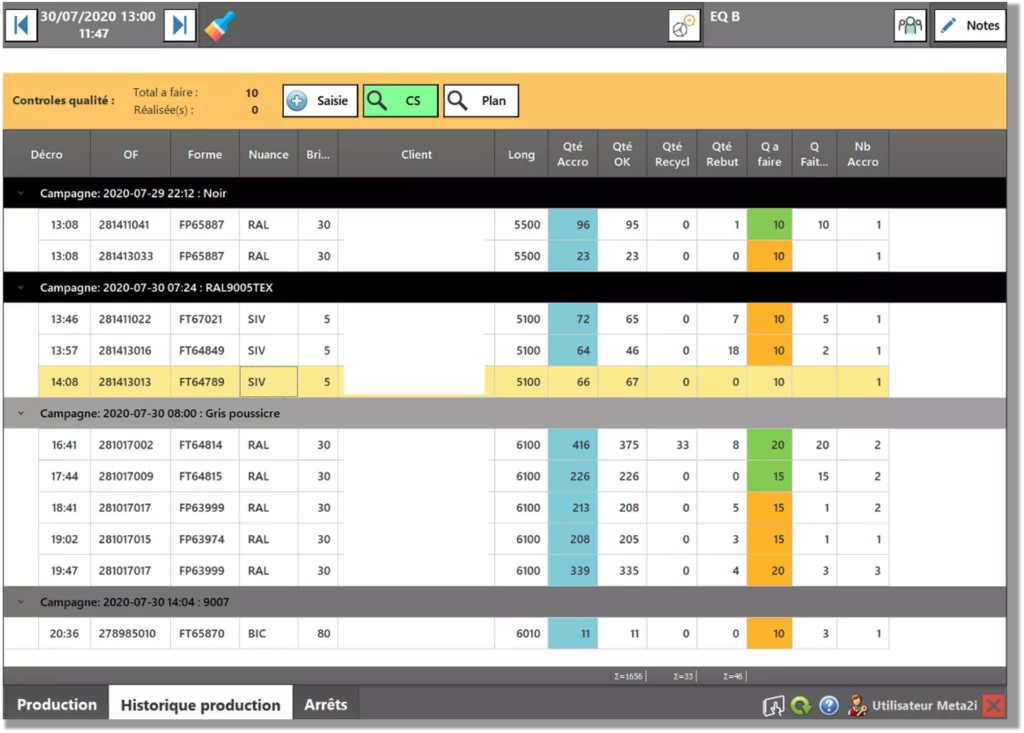

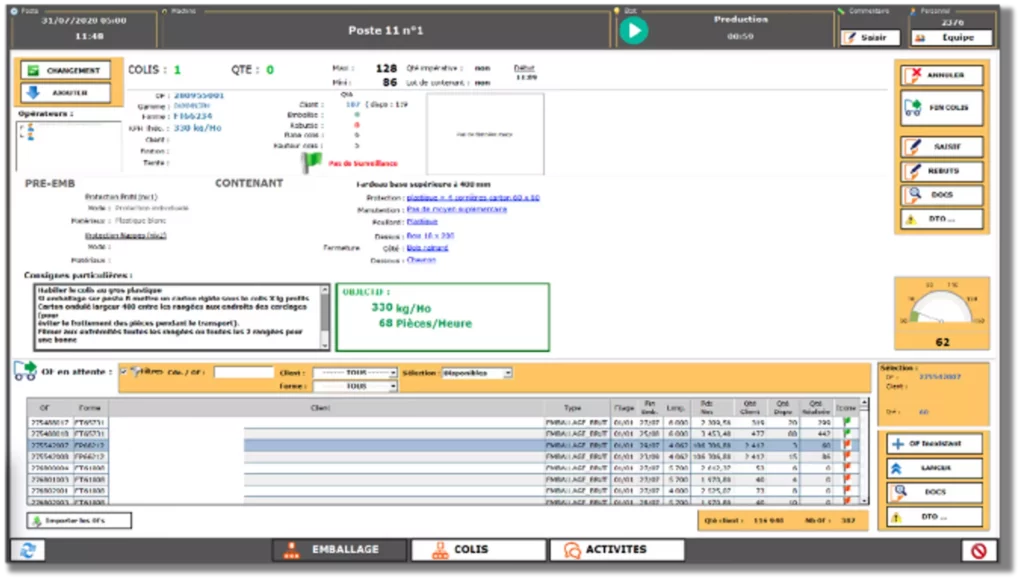

The tool allows for easier planning and better organization at all levels. Thus, KmExtrusion can manage your workshops at each stage of your production:

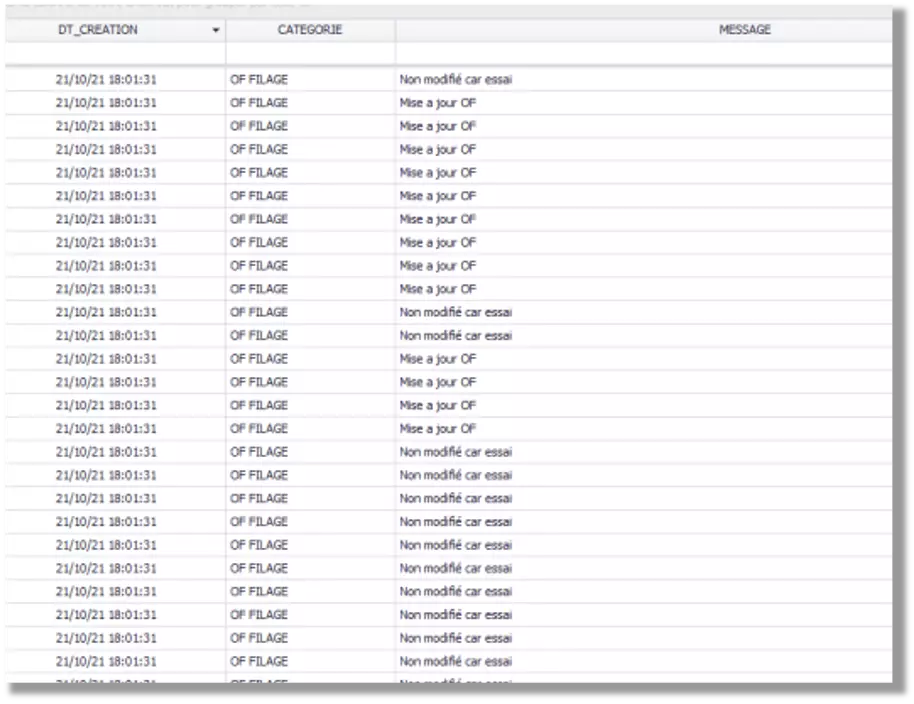

They can be executed:

- Periodically via a scheduled task, a service, or a task in the KmExtrusion database

- Manually via the KmExtrusion “Gateway” application

These exchanges are done in both directions:

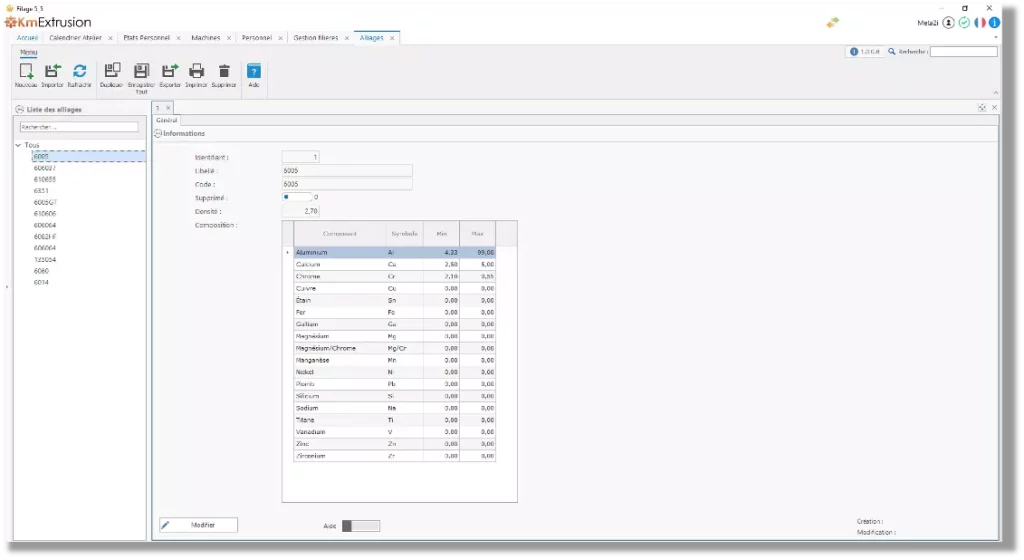

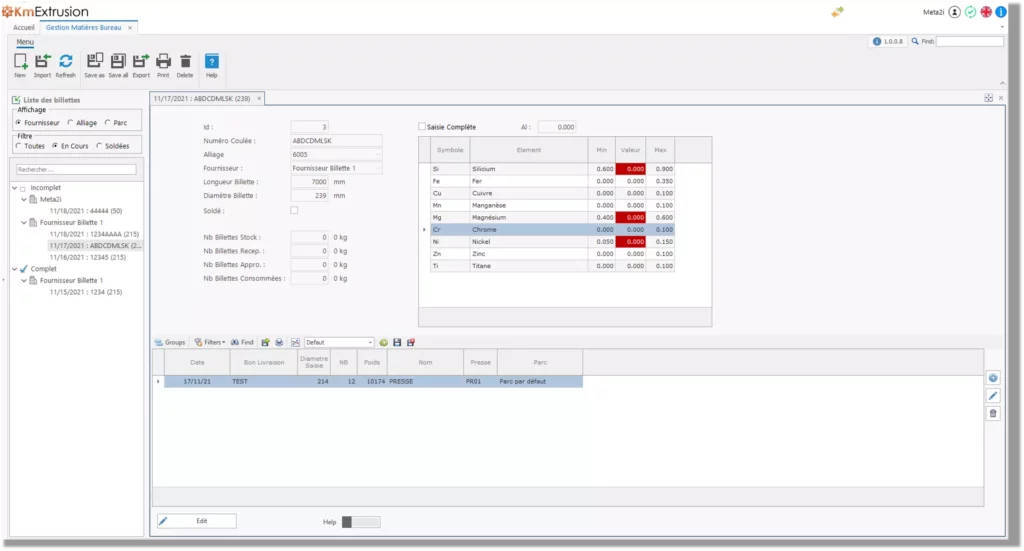

- From the ERP to KmExtrusion, which will provide :

- The shapes

- The indices

- The ranges (allowing the management of the tools)

- The order book with the Work Order

- From KmExtrusion to ERP which will provide:

- State of the tools

- Productions realized at the end of the Extrusion process

- Production passed to hardness input control

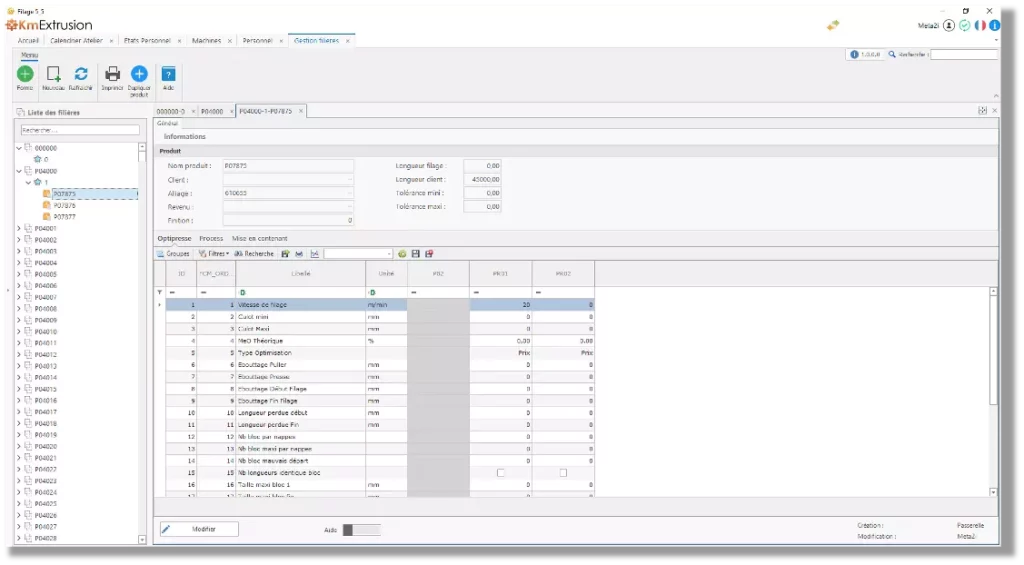

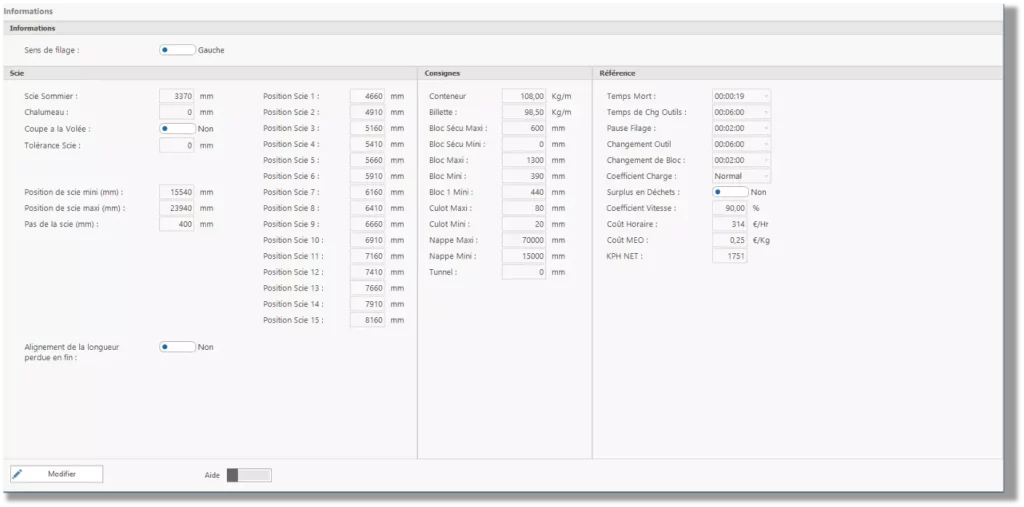

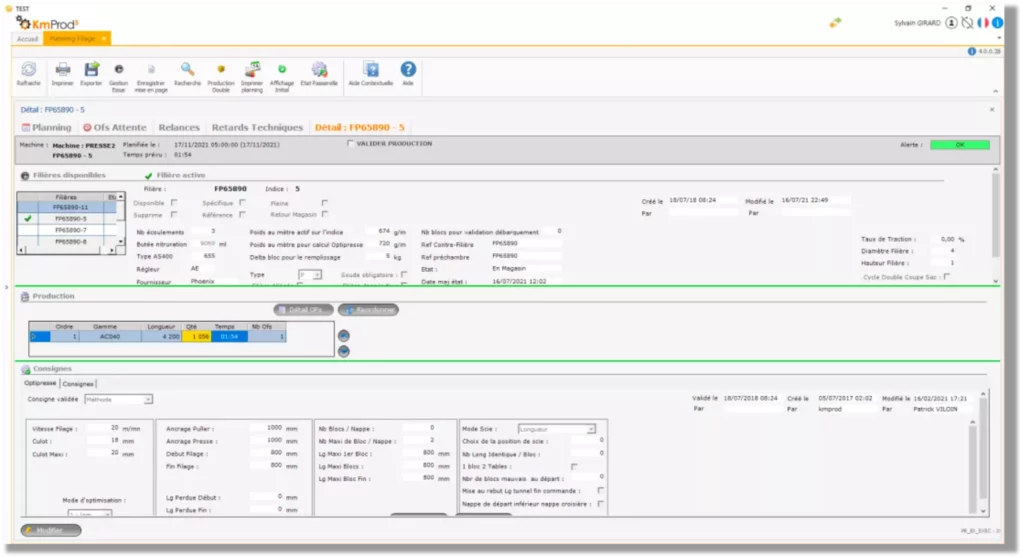

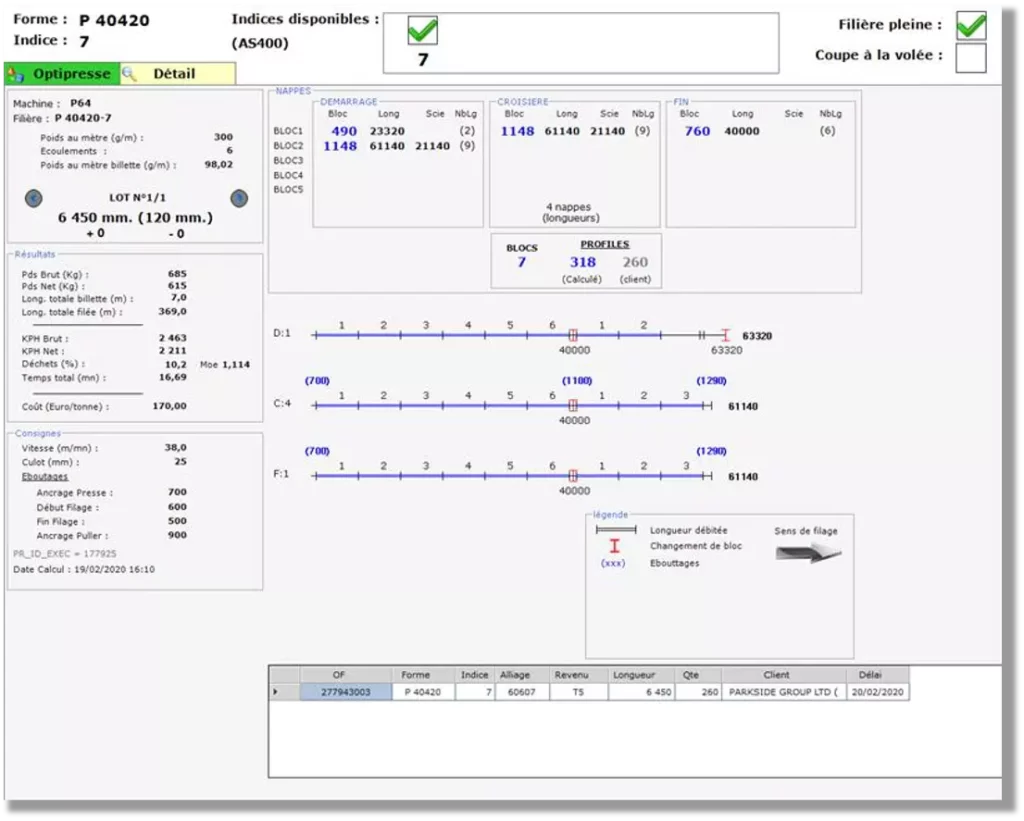

Press Configuration

A screen will allow you to configure your presses, considering all your parameters such as the direction of the extrusion, the different tolerances required, the positioning of the saws.

Instructions adapted to your process will be set up.

KmExtrusion will also configure the reference times. These indications will allow us to calculate the cost of production.

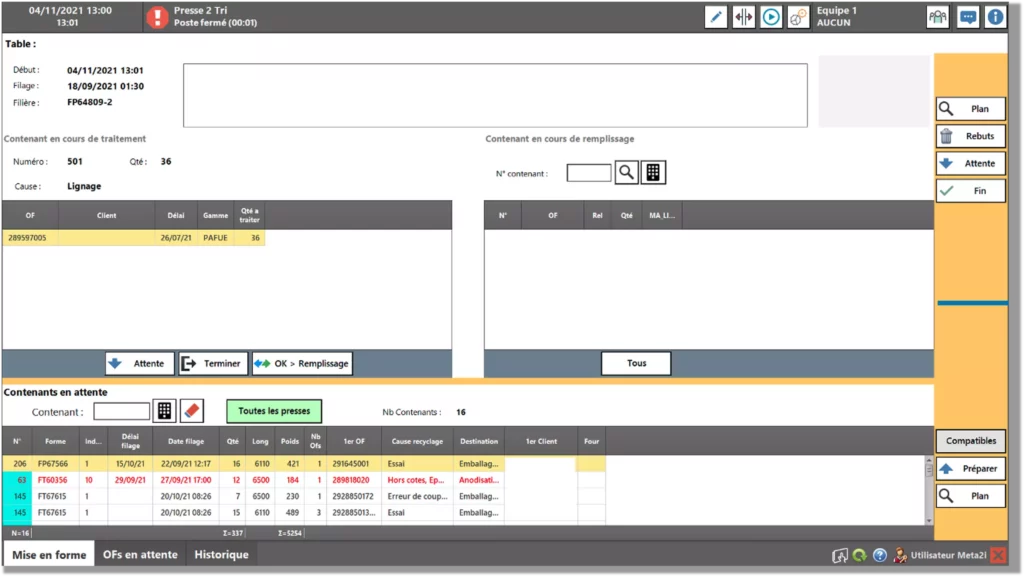

Shaping

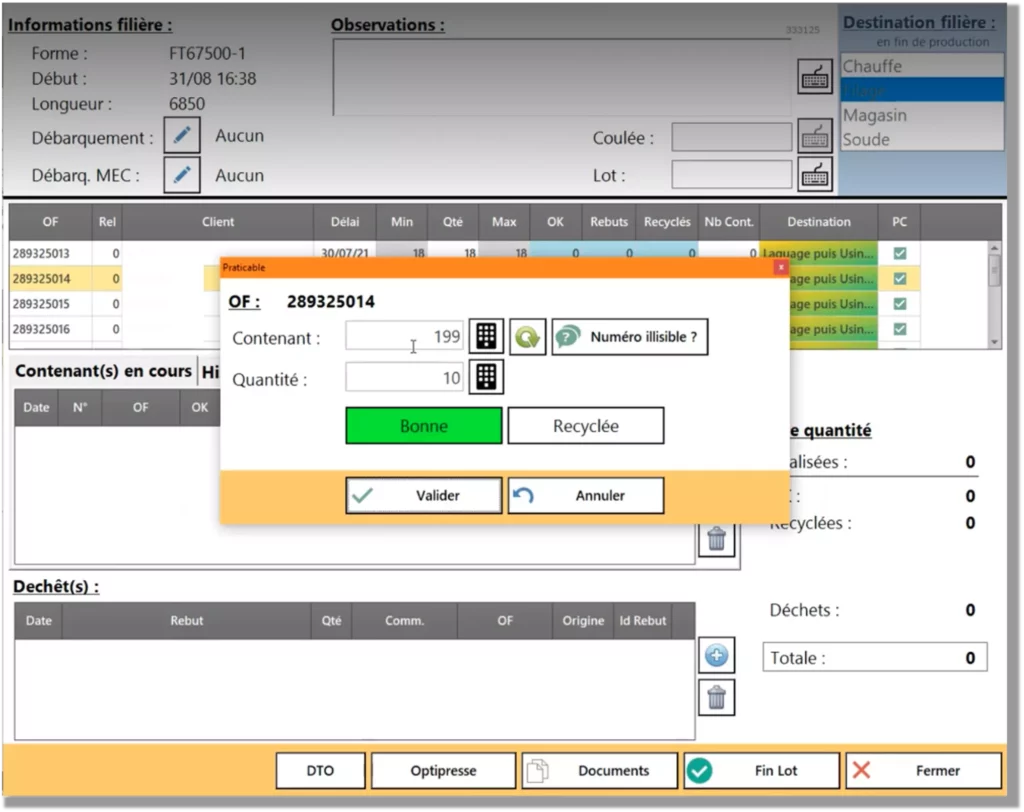

When containers are declared with items to be recycled at containerization, they are available at shaping.

Two types of solutions are managed:

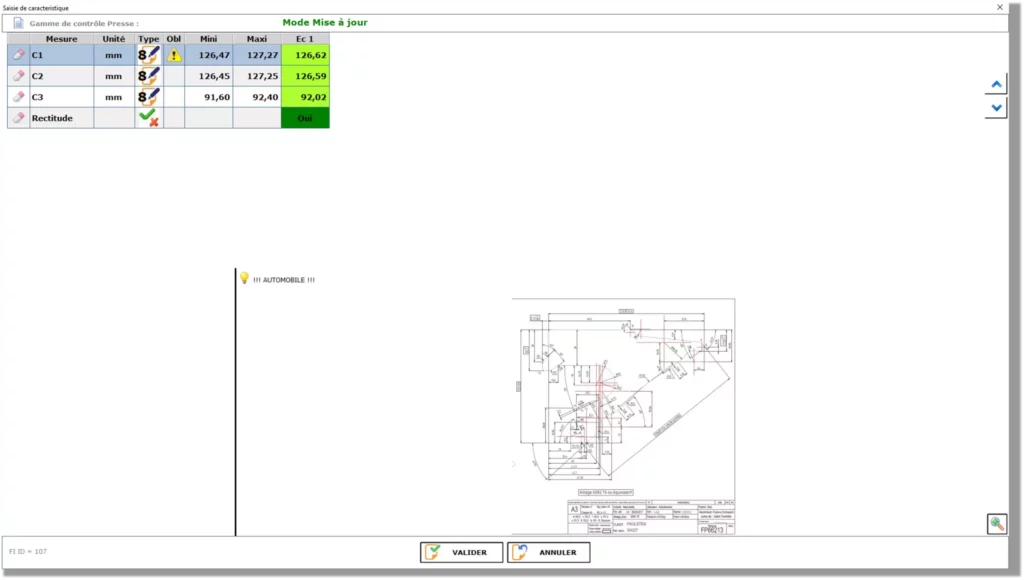

- Sorting at the presses: control on the visual aspect of the bars

- Rectification or Straightening: Correction of problems encountered (for example : geometry, traction) Depending on the choice made by the operator, the containers are available on the Sorting or Rectif screen.

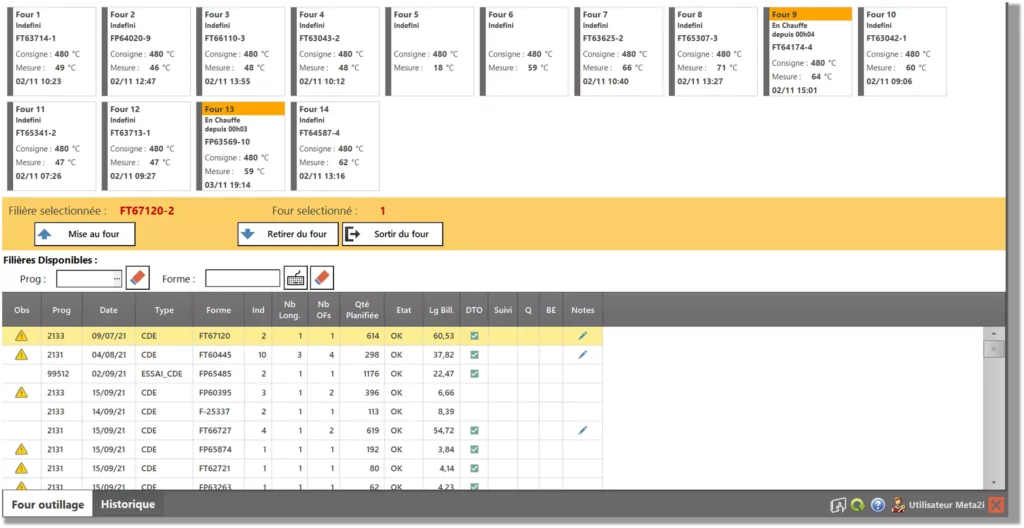

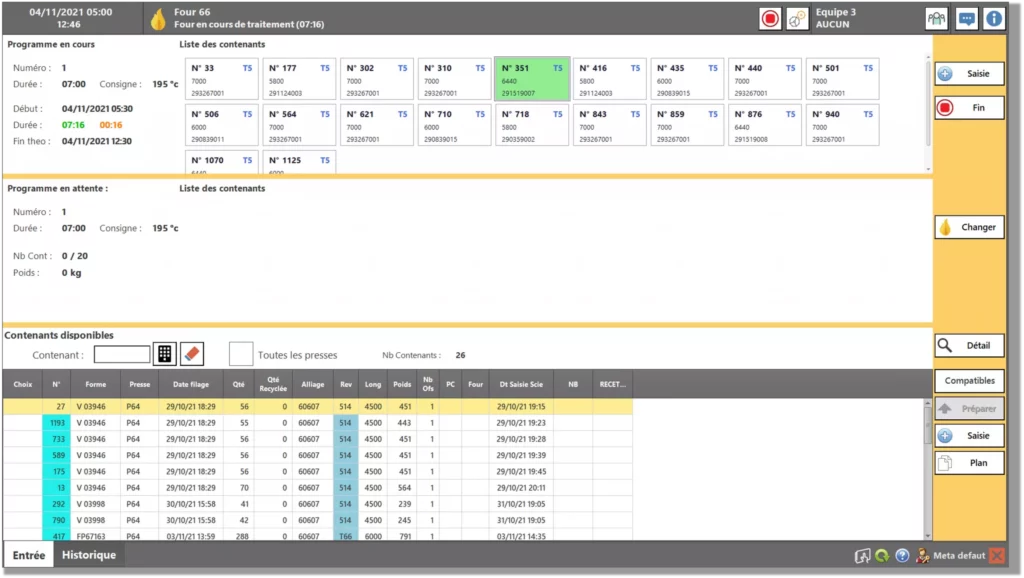

Revenue furnace

With the workshop screens, the operator can also control the tempering furnaces.

Information and alerts will be made available to him to control the passage of the containers to the furnace.

- n the same way, a traceability will be set up with : A history of the load of the furnaces (Start / end / list of containers)

- Traceability of the containers (When? Which furnace? How many passages to the furnace?)

KmExtrusion supports their performance

Our References